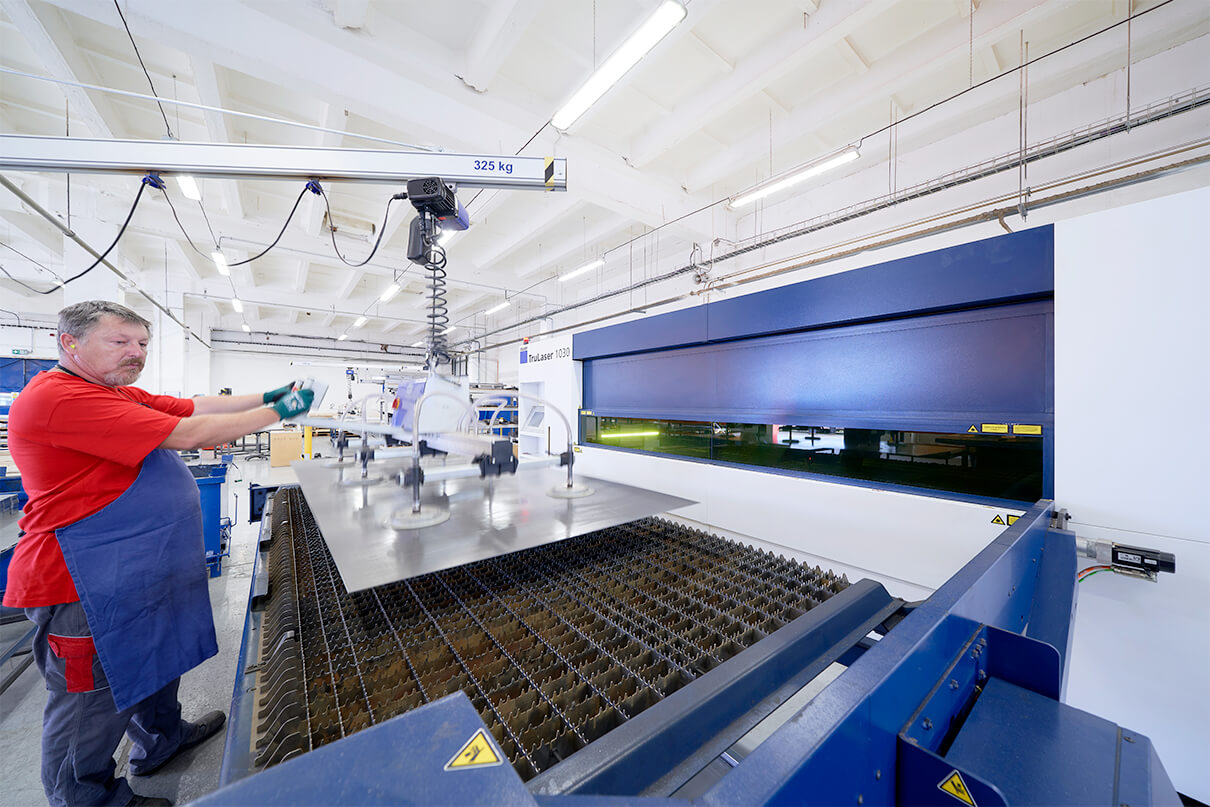

Our production – state-of-the-art and powerful

Everything that is important for our office furniture we do ourselves. This starts with the processing of chipboard, steel tubes and steel sheets and ends with the packaging, which is so enormously important for us.

Only in this way we have important processing steps in our own hands in order to produce high-quality office furniture and ensure safe shipping.

- High-bay warehouse for wooden panel materials with fully automatic, waste-optimised panel-sizing saw

- 4-sided sizing and edging line with robot stacking

- High-performance drilling and dowelling machine with automatic stacking

- CNC automatic drilling machines

- CNC machining centre for free-form wooden panels with fully automatic robot loading

- Press line for roll/stand pedestals

- Tube laser with glass fibre technology

- Flatbed laser

- Punch-Nibbling Machine

- several ben presses

- several welding robots

- ultra-modern continuous line with over 200 m chain length

- Coating according to the latest environmental standards

- quick colour changes possible

- Heating by own chip boiler

- State-of-the-art felt cutting machine with the following processing options: cutting, folding and milling.

- Very small diameters possible (e.g. for screw heads).

- Vacuum table with powerful pump for fixing the air-permeable acoustic material

- Machinery for the production of packaging made of continuous corrugated board “just in time

- several packaging lines